Manufacturing

Global

Multi site

The client

Our global manufacturing client is a market leader in industrial lubrication products, with facilities across Europe, the US and India. Over the past several years the client had been driving internal process improvements but were also looking to drive new levels of process efficiency.

The challenge

The problem the client had was in quality control. The client needed a reliable and efficient system that can accurately inspect products and alert them to any issues. Quality control is an essential part of any manufacturing process but ensuring consistent quality can be a challenge. The Client has thousands of finished goods being shipped across the world.

Prior to being shipped, each part goes through a rigorous process including an inspection and quality checks. The Client would complete up to 900 inspections a day. The process was extremely manual, it required a lot of paperwork and administrative tasks, and human error played a huge part in the process. The client required the inspection phase of the overall process to be automated.

The solution

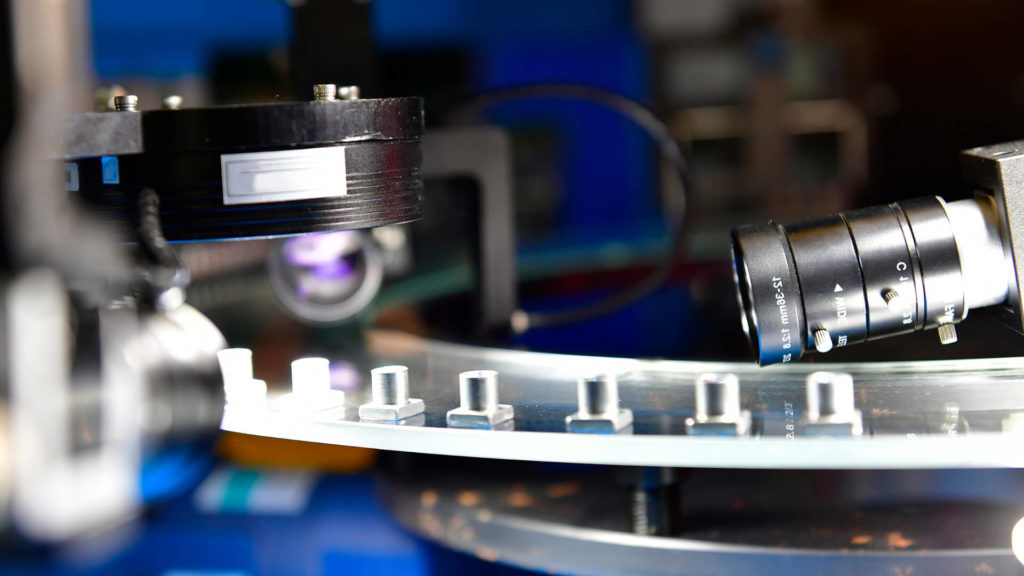

That’s where the WrxFlo Vision Inspection System came in. This cutting-edge system can help businesses reach optimal quality control in manufacturing processes by detecting even the smallest of defects, as well as identifying opportunities for improvement. With its advanced features, such as its high-speed cameras, intuitive software, and powerful analytics, the WrxFlo Vision Inspection System can provide businesses with the insights needed to ensure consistent quality.

WrxFlo looked at our clients current vision system quality inspection process and worked with them to review the portfolio of manufacturing products to agree on which areas would be set up.

WrxFlo used Advantech industrial PCs which are hooked up to industrial cameras through USB ports which are implemented onsite in the client’s manufacturing facility. The first unit is then set up. The system takes a visual record of the unit with a 100% inspection rate, which is approved by the client as 100% quality approved.

The WrxFlo solutions

Once this is created the system starts to learn and the Vision Inspection System can compare other parts to this best-in-class part.

With the click of a button, each part will go through a rigorous inspection testing phase and the VIS can detect any errors with parts. The system then notifies the operator, who can then decide a course of action. The operator can fail it or pass it, and a record of the test will be stored.

This system removes any human error, as it removes the operator’s tacit knowledge, as most quality systems are based on human experience and this system is based on machine learning. This system also removes paper as everything recorded by hand is now removed and the data is recorded and stored in the cloud for future analysis.

The result

- A fully automated system, that can accurately inspect products once they are finished manufacturing and alert them of any issues.

- Self-learning – as it learns and predict good product and bad product, which allows the client to improve the system accuracy over time.

- Cloud-based – the platform sits in the cloud; all records are stored on the cloud and on hand to the business in real time for review.

- Analytics - The system can analyse metrics and trends with errors/faults