The collection and analysis of data across the supply chain can be of tremendous value as it creates greater visibility and efficiencies within processes. The right data can help improve a company’s supply chain management by providing greater insights into all levels of its operations.

To drive change in the supply chain requires insights into a company’s processes, and how that data is collected and made accessible for interpretation can determine the level of improvement a business can make. However, a business must first gather all its vital data before it can use this to refine its business processes.

Data collection challenges

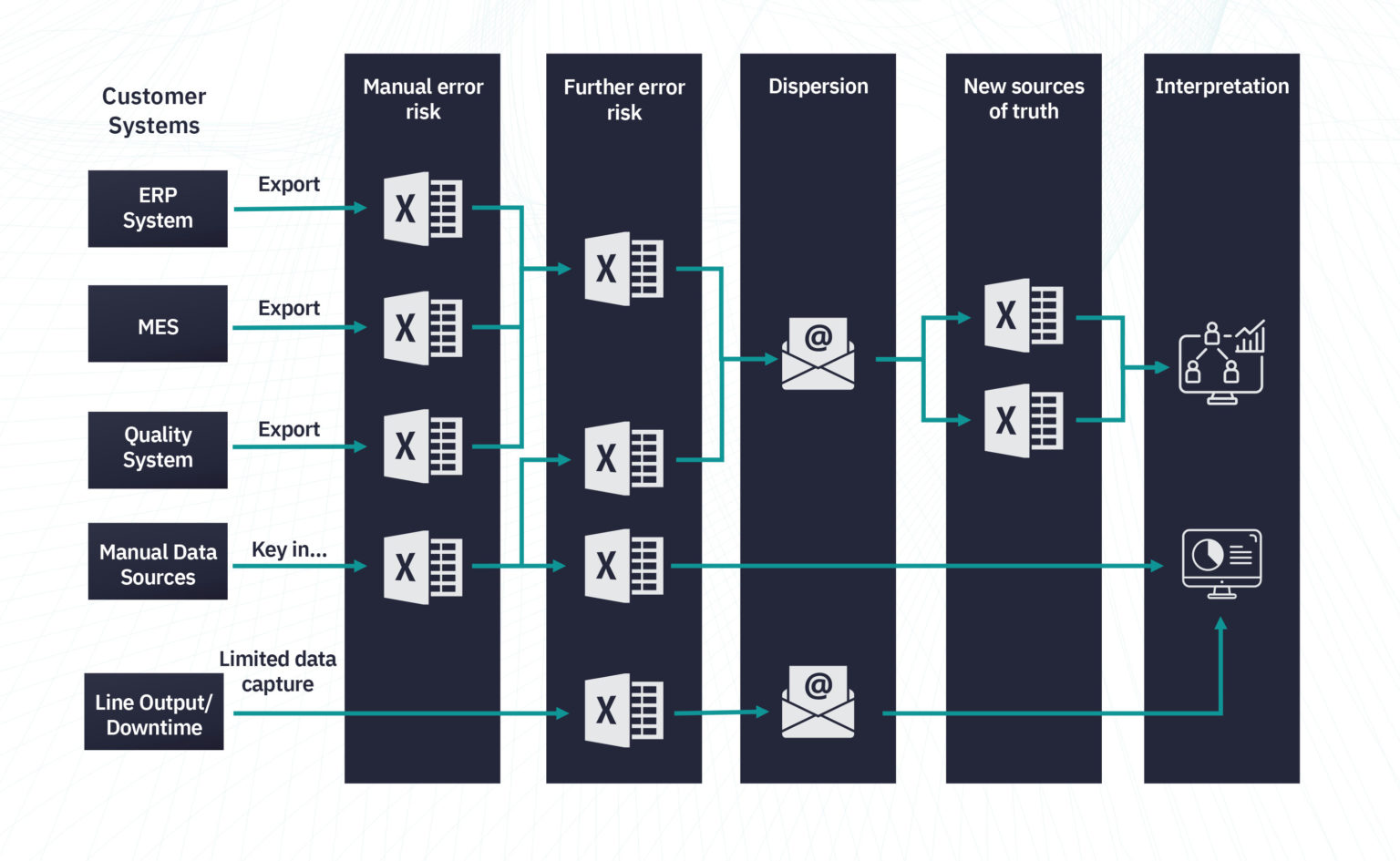

Data collection can be challenging for every business, with many common data collection issues to overcome. Useful data is often dispersed across key business systems and applications needed to run operations. These include enterprise resource planning software (ERPs), execution manufacturing systems (EMS) and total quality management tools (TQM), etc. These systems are often not connected to each other, and there can be gaps in functionality, filled by manual efforts.

There is often no industrywide system in use, with businesses building their processes on customised versions of software. This makes it costly to change these systems, forcing businesses to use outdated or unfit systems. In many cases, Excel is used extensively to capture and analyse data. The successful operation of Excel processes can often be down to the operation of a few individual team members and can involve much manual data input.

With any manual process, there are many opportunities for human error. There may be errors with data input, data consolidation, dispersion of data, latency issues, conflicting interpretations of data or multiple sources of truth.

Data collection & analytics with Industry 4.0

To reduce error and improve information latency, industry 4.0 technologies can be implemented to provide access to data in real time. With up-to-date information, a business can avoid costly delays and solve issues before they arise. See our article on how lean and technology can combine to yield continuous improvements.

There are three main ways data is collected: automated digital processes, data processing systems and lastly manual data capture.

Data processing systems

Many businesses use various ERP, MES and Quality systems to run their operations. These are often siloed, have gaps in functionality or are no longer fit for purpose. Modern platforms can connect to these systems while also facilitating human input and IoT collection, removing any gaps in data collection.

Manual data collection

While the future of the supply chain will be largely automated with robotics, for many businesses this is still too costly. Manual data collection will continue to be cost effective for a variety of industries.

Manual data collection was traditionally time consuming, involving data capture on paper-based forms, transportation delays from factory or warehouse floor to management offices and input to desktop based system. This process took significant manual hours, with a drawn-out process that sometimes meant data was not useful in any meaningful way for up to months.

With new technologies, this can be largely streamlined. Data capture can be done on tablets or using handheld scanners, with data fed in real-time to management systems.

IoT data collection

With the advent of modern technologies, the smart factory is accessible for logistics and manufacturing companies of all scales. IoT or Internet of Things data capture uses built-in scanners to connect all systems and applications in a process or facility. This data capture can use wired ethernet connections, or with 5G networks systems can be connected wirelessly.

Storing process data in the cloud

The volume of data produced by some processes can be so vast, that it was not feasible for smaller producers to store this data locally. With cloud servers hosted by the likes of Amazon’s AWS, the data of multiple systems can be interconnected and accessed globally. This provides huge advantages for remote working and logistics companies with operations spread out over large geographical areas.

How to set up IoT data collection?

Newer systems often come with inbuilt scanners, but older systems can be fitted with IoT scanners. These are easy and fast to onboard, configure, monitor, and scale across all locations, and can automate data collection processes within days.

There are many types of IoT sensors, including:

- Acceleration and Vibration Sensors

- Humidity Sensors

- Level Sensors

- Pressure Sensors

- Proximity Sensors

- Sound Sensors

- Temperature Sensors

- Vision Sensors

Real-time data insights with WrxFlo

WrxFlo becomes your partner in your digital transformation. Our WrxFlo platform can connect to your existing systems and fill in any missing functionality. We can also implement data capture across all your processes and bring this data together in the cloud, where you can gain real-time insights on dashboards custom designed for your company.

With WrxFlo, you can eliminate manual error, have greater accountability and highlight any upcoming gaps and opportunities.

To see how WrxFlo can transform your people, processes and technology, contact us or request a demo here.