Quality control is an essential part of any manufacturing process but ensuring consistent quality can be a challenge. You need a reliable and efficient system that can accurately inspect your products and alert you to any issues. That’s where the WrxFlo Vision Inspection System comes in. This cutting-edge system can help you reach optimal quality control in your manufacturing process by detecting even the smallest of defects, as well as identifying opportunities for improvement. With its advanced features, such as its high-speed cameras, intuitive software, and powerful analytics, the WrxFlo Vision Inspection System can provide you with the insights you need to ensure consistent quality.

What is the WrxFlo Vision Inspection System?

The WrxFlo vision inspection system is a system used to detect defects, contaminants, functional flaws, and other irregularities in manufactured products, which improves quality and reduces costs for businesses. Thus, simplifying and optimising your manual quality process.

Benefits of the WrxFlo Vision Inspection System

-

Take Control of Your Manufacturing Quality

Including a machine vision inspection system in the manufacturing process has various advantages, notably in terms of efficiency. Because vision inspection can precisely examine each product, manufacturers may have more peace of mind knowing that no product will leave the facility until it is in perfect condition. This adds an extra layer of trademark protection, reduces rework, the chance of certain product recalls, and product waste, and improves overall process efficiency.

-

Reduces Downtime

A vision system protects against component damage by eliminating physical touch between a test system and manufactured parts. It also saves the time and cost of repairing mechanical components when they wear out. As machines require less supervision, operation times rise, allowing you to fulfil production deadlines with ease and regularity.

-

Anomaly Detection

Machine vision can identify product flaws such as surface dents and scratches. The aim is to properly apply detection boundaries to identify “acceptable” errors from “unacceptable” problems. Nevertheless, machine vision is great for these tasks since it works on examples rather than strict rules.

-

Increases Throughput

Decreased downtime always leads to improved throughput. A vision system, on the other hand, takes this notion a step further. It can provide remedial commands around one second faster than qualified operators. This lowers the need for manual system correction and helps to maintain production levels.

Features of the WrxFlo Vision Inspection System

The features of the WrxFlo Vision Inspection System include the following:

- This is a visual quality automated inspection system

- Takes seconds rather than minutes

- The information is saved to the cloud and the data can be analysed.

- Removes a manual inspection process and brings the process to a new level of automation.

How the WrxFlo Vision Inspection System works

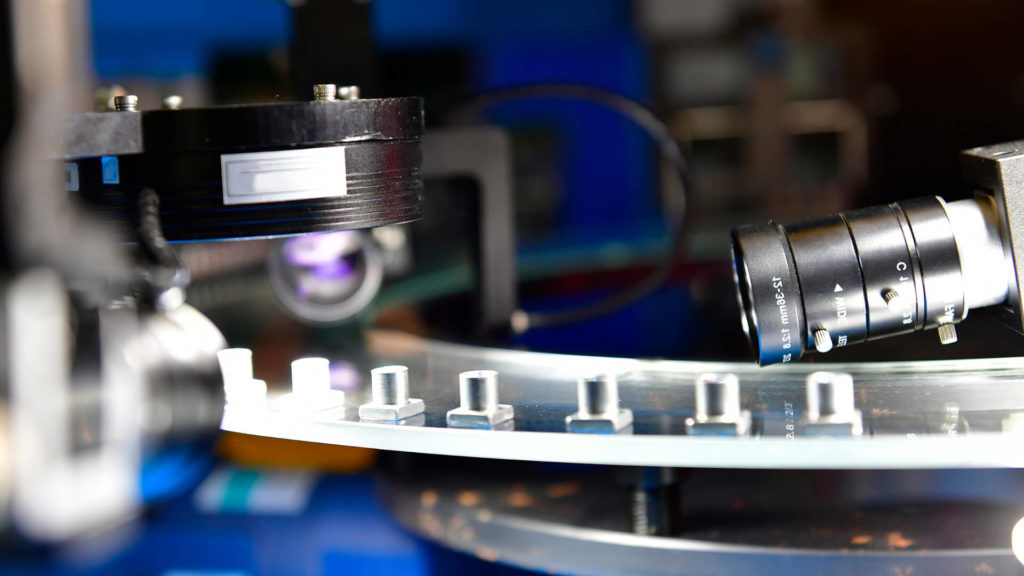

We work with the client to review the portfolio of manufacturing products to agree on which areas would be set up. WrxFlo uses Advantech industrial PCs which are hooked up to industrial cameras through USB ports which are implemented onsite in the client’s manufacturing facility.

When a product is finished being manufactured, it must go through quality inspection. WrxFlo system takes a visual record of the unit with a 100% inspection rate, which is approved by the client as 100% quality approved.

Once this is created the system is learning and WrxFlo can compare other parts to this best-in-class part. With the click of a button, each part will go through a rigorous inspection testing phase and the WrxFlo system can detect any errors with parts. The system then notifies the operator, who can then decide a course of action. The operator can fail it or pass it, and a record of the test will be stored.

This system removes any human error, as it removes the operator’s tacit knowledge, as most quality systems are based on human experience and this system is based on machine learning. This system also removes paper as everything recorded by hand is now removed and the data is recorded and stored in the cloud for future analysis.

WrxFlo Vision Inspection System capabilities

In order to be successful with the WrxFlo Vision Inspection System, you need to understand the following:

– The WrxFlo Vision Inspection System can inspect products with speed and precision, enhancing production line flow.

– The WrxFlo Vision Inspection System can understand and record movement data for future use in order to improve the accuracy of the inspection.

– The WrxFlo Vision Inspection System provides quality service to businesses with minimal installation and removal efforts.

This allows for immediate feedback and changes that are made quickly and without human interaction.

Conclusion

The Vision Inspection System enables automatic quality control, allowing you to enjoy a dependable system that consistently delivers. As a result, you can be confident that every product your company produces will match the needs of its clients.

Bottom line, inspection systems improve quality, enhance efficiency, and reduce production costs. If you’d like to learn more about the WrxFlo Vision System or other solutions, contact a member of the team for a demo.