2025 | By The Wrxflo Team

Is Your ERP Failing at the Box Level? The Inefficient Truth About Pallet Picking.

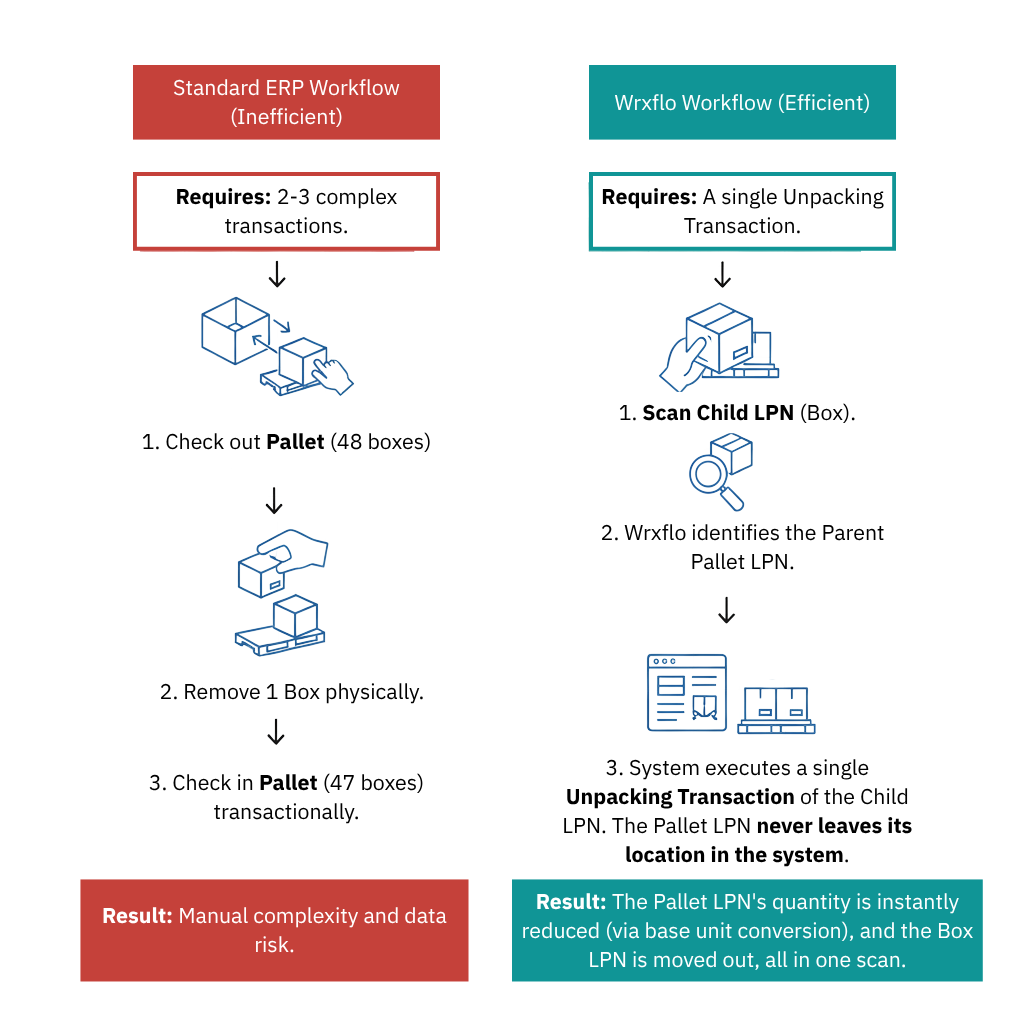

Many warehouse management and ERP systems struggle when inventory drops below the pallet level. Our recent conversations with clients consistently highlight one major pain point: the moment a single Box needs to be removed from a Pallet, the system forces a complicated, multi-step transaction.

The old, inefficient workflow requires checking out the entire Pallet, physically removing the item, and then logging the Pallet back in with a new, reduced quantity. This creates unnecessary transaction volume, slows down your pickers, and introduces a risk of critical data errors.

The solution isn’t just to track smaller units—it’s to manage the relationship between them. Wrxflo is purpose-built to eliminate this friction and manage hierarchical inventory seamlessly.

How Wrxflo Masters Dynamic Unit of Measure (UOM) Tracking

Wrxflo is not constrained by static inventory layers. We designed our platform architecture around two fundamental principles to handle complex UOM and partial picking:

1. Fixed Base Unit Capability

At its core, Wrxflo ensures absolute inventory accuracy by leveraging a Fixed Base Unit of Measure (UOM – Unit of Measure). This is typically the smallest sellable or trackable unit of an item (e.g., an ‘each’).

- Universal Visibility: All stock is fundamentally inventoried using this base unit, ensuring 100% accurate quantity visibility across the warehouse.

- Intelligent Conversions: Administrators define unlimited conversion relationships (e.g., 1 Box = 12 Eaches; 1 Pallet = 48 Boxes). The system handles all mathematical conversions automatically, allowing your team to transact in Pallets, Boxes, or Eaches without manual calculation errors.

2. Dynamic Mixed Tracking via License Plate Numbers (LPNs)

The magic ingredient is our sophisticated License Plate Number (LPN) system, which manages mixed inventory and allows for dynamic sub-unit removal without disrupting the parent container.

Core Solution Mechanism:

An LPN is a container barcode (the ‘license plate’) that can be applied to any level of inventory—a Pallet (Parent LPN), a Tote, or even an individual Box (Child LPN). Wrxflo maintains the parent-child relationship in real-time.

Solving the Partial Pick Problem:

When a single Box needs to be removed from a Pallet LPN, Wrxflo facilitates a single, efficient transaction:

To Summarise the points above

Wrxflo allows you to track and manage a mix of fully checked-in Pallets, partially depleted Pallets, and loose Boxes (LPNs or single units) simultaneously across various locations at any given time. We provide the granular control of tracking at the box level while maintaining the speed and efficiency necessary for moving inventory at the pallet level.

Stop fighting your ERP to reflect reality. Start using Wrxflo.

Ready to see a live demo of flexible inventory management?

Contact the Wrxflo team today to schedule a walkthrough of our WMS/ERP platform and see how we eliminate complex transactions for good.