New digital technologies have transformed every industry including manufacturing, production and logistics, providing new opportunities and better efficiencies. The benefits of digital transformation are increasingly obvious in the face of a challenging global supply chain and the pandemic.

What is digital transformation?

Digital transformation in manufacturing helps businesses automate business processes and solve challenges using emerging technologies. These technologies include the Internet of Things (IoT), AI, big data, cloud storage and remote access.

There are transformative benefits to organisations that fully embrace digital technology, including increasing of productivity, reducing downtime, optimising human resources and boosting overall productivity. Digital Transformation brings together the cornerstones of production: people, processes and technology.

Using digital transformation to tackle manufacturing obstacles

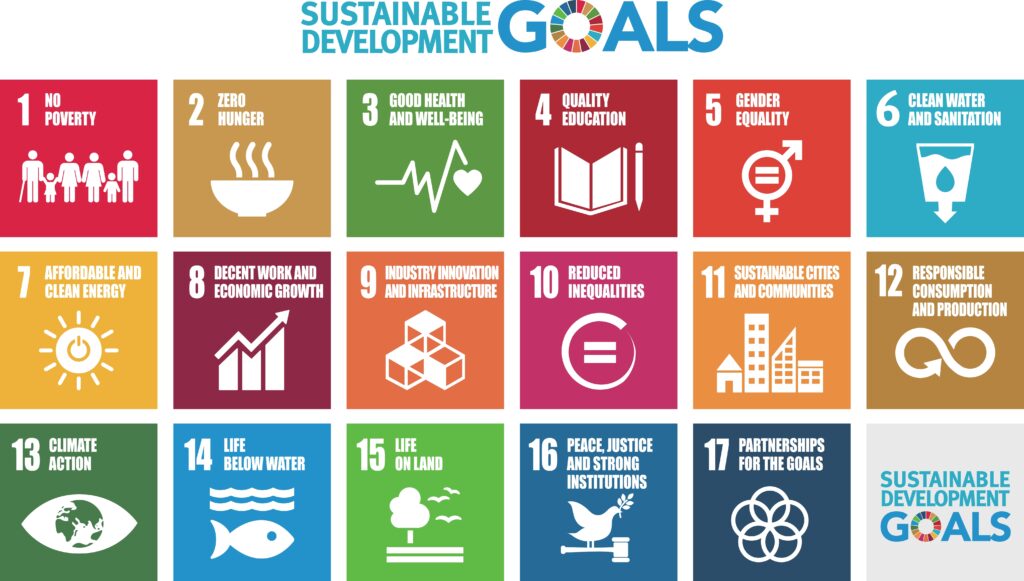

As well as top-level benefits of improved efficiencies and cost reduction, there are also many environmental and social benefits.

There are a range of benefits for manufacturers to go digital, and take advantage of the government’s new, Grow Digital Fund

Reducing costs with greater insights

Digital transformation can provide greater insights into manufacturing and logistics processes, exposing issues and inefficiencies in the supply chain. This allows businesses to make informed decisions in real-time, rather than needing to wait for a monthly or quarterly report to analyse issues. This rapid transformation enables manufacturers to reduce costs on inefficient machines, reduce downtime, free up warehousing space with more accurate stock levels and save critical time across production.

Not only will costs be reduced, transformation can allow a quicker delivery to end customers, as supply chains run more efficiently.

Improved sustainability

In a recent study, 40% of executives believe that digital technologies are already having a positive impact on their sustainability goals. By utilising greater automated data collection, and monitoring equipment performance in real-time, manufacturers can improve their overall efficiency and reduce waste. Alongside efficiency improvements, data input devices allow companies to reduce paper usage by up to 100%.

Using IoT to constantly measure all processes

Internet of Things, or IoT devices are becoming increasingly affordable and sophisticated, offering manufacturers a greater level of information on their existing processes and machinery. IoT sensors are vital for collecting essential process data and sending this to the cloud for analysis, automating what was previously a challenging manual task. Information can be stored locally in servers or in cloud databases, and can be accessed anywhere in the world with the right system.

With 5G networks, an entire factory floor can be monitored wirelessly, with data sent for analysis alongside other business critical information. Creating a smart factory with IoT sensors can transform how a business operates. With real-time data they provide a range of insights to equipment downtime monitoring, productivity of devices, processes and production and better overall factory visibility.

Business improvements can be near endless, and help manufacturers improve efficiencies and reduce costs, including:

- Use predictive maintenance to minimise downtime

- Improve forecasting

- Better visibility of stock levels

- Improved product quality

- More accurate production estimates and better communication with customers

Reallocation human resources

HR digital transformation is where the implementation of new technologies allows a company to reallocation human resources away from tasks such as manual data capture. The main goal of HR digital transformation is reducing the amount of time spend on repetitive tasks and to automate processes, while also improving the employee experience.

In essence, management teams can be freed from spending hours pulling data from reports; floor teams can be saved time manually gathering data or doing manual input into paper-based formats, and subsequently having to transfer this manual data to another system. It frees team from data capture report generation and allows them to shift their focus to value delivery.

WrxFlo is your partner on your digital transformation

WrxFlo aim to be the partner on your digital transformation. Our platform has been built from the ground up to help the supply chain run more efficiently. It utilises sensors to track all your data in real-time, add new functionality to outdated ERP systems, store your data securely and offer access to this anywhere in the world. With our data visualisation screens created for each customer we help you understand the KPIs that bring most value to your business, and help you realise your digital transformation.

Talk to us today and Request a Demo to see how WrxFlo can you revolutise your people, process and technology.